I initially set out to provide the lowest cost, highest value, rocker plates to the masses because (at the time) the highest functioning rocker plates were $1,000+ USD. With inspiration from the Rocker Plates Facebook group I came up with the V1 of the Ride South rocker plate which I released the plans for free. I then started working on a V2 version which I had planned to sell for the low cost of $350 USD.

Fast forward to now and few dozen rocker plates sold and I just do not have the time to support the side project coupled with the fact that multiple “companies” have taken my plans and are now selling them as their own with very little modification. I have decided to just release all of the plans and source files and that is what this webpage is for.

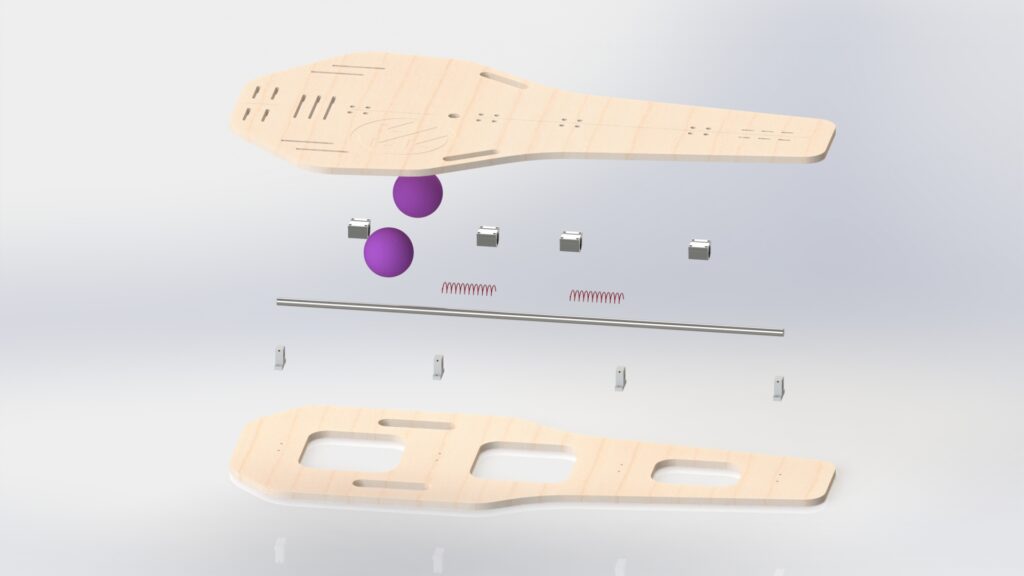

Parts List

In the manner of transparency, the links in the below table are mostly affiliate links where applicable. It costs you nothing to click them and helps me justify making more things to release for free in the future. (also worth noting, these are all parts required for the project and not random crap I am trying to sell you.)

| # | PART | PART # | SIZE | QTY | Ali | eBay | Amazon | Grainger | Allied |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Top Plate | DIY | 18mm Birch Plywood | 1 | – | – | – | – | – |

| 2 | Bottom Plate | DIY | 18mm Birch Plywood | 1 | – | – | – | – | – |

| 3 | Risers | DIY | 3mm wood/plexi/delrin | 4 | – | – | – | – | – |

| 4 | Bullseye Level o | 2H366 | 37mm x 7mm | 1 | link | link | link | – | – |

| 5 | Linear Rod | 32*7 | 20mm x 1400mm (55″) | 1 | – | link | link | – | – |

| 6 | Linear Bearing | SCS20UU/SBR20UU | 4 | link | link | link | – | – | |

| 7 | Linear Rod Support | SK20 | 4 | link | link | link | – | – | |

| 8 | Springs | 121292 | 137mm x 27mm | 2 | – | – | link | – | link |

| 9 | Top Plate Bolts | 26LG41 | M6-1.0 25mm/30mm | 16 | – | link | link | – | – |

| 10 | Bottom Plate Bolts | 6EY59 | M6-1.0 30mm | 16 | – | link | link | – | – |

| 11 | Top Plate Washers | 29DH69 | M6 x 12 | 8 | – | link | link | – | – |

| 12 | Bottom Plate Lock Nuts | 26LJ85 | M6-1.0 | 8 | – | link | link | – | – |

| 13 | Inflatable Play Balls | B07BGV41R7 | 5″ | 2 | – | link | link | – | – |

| 14 | Stage Clamps o | 2 | – | – | link | – | – | ||

| 15 | Velcro Straps o | 3 | – | – | link | – | – | ||

Notes

- If you decide to go with SCS20UU bearings YOU WILL NEED RISERS.

- The V3 rocker plate design DOES NOT support SBR20UUs.

Files

| PART | SBR20UU | SCS20UU | MEASUREMENTS | PRINTABLES |

|---|---|---|---|---|

| Top Plate V1 | Google Drive | Google Drive | Single / Multi | |

| Bottom Plate V1 | Google Drive | Google Drive | Single / Multi | |

| Top Plate V3 | Google Drive | |||

| Bottom Plate V3 | Google Drive | |||

| Riser | Google Drive | Google Drive | ||

F.A.Q.

- Does this rocker plate have fore/aft & side to side movement?

yes. - What is the difference between SBR20UU and SCS20UU?

mounting bolt pattern and stack height of bearing. - Will you supply your source files?

no.

Love the video and instructions. I noticed a bunch of the affiliate links are busted and would love for you to get something from all this work. Do you have new links or recommendations for substitutions?

Aaron,

Thanks! I’m working on converting everything over to this web page (away from the excel sheet that gets stagnant) and getting all of the links updated. I should have them done by this weekend.

I’ve went thru the parts list and the only thing I cannot find is the 20mm Linear Rod at 1400mm or 55″ long. I will continue looking.

Hi Andrew,

Love your project, thank you for sharing.

Did you end up finding the 20mm Linear Rod?

I haven’t found any online, but I do have some I can sell if you’re still interested.

I am assuming a 1200mm linear bearing will not work with this design? There is a kit currently listed on Amazon that includes (4) bearings, (2) 20mm x 1200mm linear rods, and (4) linear rod supports for $40.

Paul,

You cannot go shorter on my specific design as the linear rod mounts are positioned for the 1400mm, but you can go longer, you’ll just have some rod sticking out the front or back. Hope that helps.

couldn’t you cut the rod to 55″/1400mm?

I’ve also had a tough time finding 20x1400mm linear rods. do you happen to still have any to sell?

I have some if you’re local to the Dallas, TX area. Unfortunately I cannot ship them.

Hi, 1200mm would work if you just used different mounting holes yes? Or is the length crucial for functionality?

If you use 1200mm rod you will have to adjust all of the mounting points. The springs I selected will allow for around 200-220mm of movement so you will need to make sure you have enough space on each side of the bearings so that they won’t collide with the standoffs.

I’d sell you one for 40$; unfortunately, the shipping on one is going to be ridiculously high as they are very heavy and long. Those are the type of bolts I migrated to.

If anyone is looking I finally found 20mm x 60” rods decently priced on vxb.com for $57 shipped from the west coast to east coast.

Hi is there any chance that you could send me the files to my email account please

I’m in Fort Worth and will take you up on the offer for the rod for $40. Please email me.

what is the center line on the V1 top plate? decorative of integral to the design?

It is for centering your trainer/bike. Even weight distribution is important to the mechanics of the plate. If you are not evenly distributed you will feel the difference pretty quickly.

gotcha, so its just a shallow groove for indicating the center. Just asking incase the guy operating the CNC router has a question when he is making the cuts.

Hello Andrew,

Thank you for making your plan available, this helps so much. I am building your design. I found a local cnc shop that will cut the plates. Can I ask you to email me the files for them to use? Thank you.

Dar Webb,

The files are all available from google drive in the “Files” section on post. You should be able to click the google drive link to directly download them. I hope this helps.

I’m sorry, I know nothing about these DXF files. I did download those, but it just shows the two plates with no measurements. Is that all I have to give to the CNC shop?

Thank you

Yes, those files contain the measurements for the person operating the CNC software.

Thank you very much Andrew, I appreciate it.

Great project and well presented. Thank you for sharing such an awesome idea I Located all the components except the balls. I tried Amazon but could not find that item number

I will improvise on the top and bottom as no cnc guys around my area

Hi Andrew,

If I were to use the riser plates, for the SBR20UU bearings, do you know what size bolts I would need to use?

Thank you

Hey Andrew! I know you’re swamped, but I’m in the DFW area and would love to discuss commissioning one of these from you if you’re able – if not, I’d settle for sourcing one of those rods that seem to be so hard to come by. Please let me know!

Spencer, thanks for reaching out! I am sending you an email now.

Andrew, I don’t want to impose, but wonder if you have any more of the rods available in DFW?

Yes sir I do, shoot me an email at andrew at andrewgrabbs dot com.

Steve, thanks! The compression springs can be bought via this direct link to Allied: https://us.rs-online.com/product/rs-pro/121292/70636054/?m=70636054. I’ll update the post as well. Hope this helps.

I found some springs at McMaster Carr that look like they will work:

https://www.mcmaster.com/2006N466/

so you didn’t have any trouble mounting the bearings with the above design?

Chris I am going to purchase that same kit. Would you mind sending me the measurements for your mounting points, please?

Thanks, this is awesome. Do you know if this fits the wahoo kickr core?

You’re welcome! Thanks for giving it a read. The V2 design will fit the Wahoo KICKR Core.

Hello Andrew,

that is a very interesting project. Thanks for all your effort.

I would like to set up a V2 board for my kickr core configuration, but sadly there is no link on your Google drive.

Could you please send me a working link or forward the zip file to my email?

Hi Andrew,

This is fantastic! Just dove in and ordered a bunch of parts and found a cnc guy in my area. I have a Kickr Core, so it looks like I need the v2 .dxf files but it looks like the link is broken. Could I get you to send me those? Thanks!

Hi there,

I was wondering if you had the files for the V2 that would fit the Kickr Core? I have the Core version with the straight support legs.

Cheers

Thanks for your design. I hope to get one of these set up, but I need to find a local CNC shop. Also, would it be possible for me to edit the design to allow for a 1200 mm rod isntead?

Hey Andrew!

I really like you project, but I guess it will not work with Elite Drivo I, which I own.

Is there any chance that you can adjust your project to this trainer?

Cheers!

Piotr,

Thank you! Unfortunately at this time I don’t have the capacity to adjust the project; however, I have had people use Elite Diretos with my particular design. I hope that helps!

Sorry for the delayed response, here is the link for the riser plate:

https://drive.google.com/file/d/1_RapH79j7H7eBe2XD-JVfd-4K1QpUmD1/view?usp=sharing

Risers I saw the dimensions on your DXF file. Is this a piece of wood or metal? And what is the thickness?

It can be wood/metal/plastic/. I have used wood and rubber (skateboard truck risers off amazon). Anywhere from 3mm to 5mm. It can’t hurt to use more, it’s just going to raise the top deck.

Domenico, thanks! I would be lying if I told you I knew anything about compression rates of springs. A lot of this has been done solely based on “feel”. I’d suggest giving it a shot.

Thank you! I would recommend shopping on ebay/aliexpress for the parts. I’m not sure what suppliers are available in Italy, so I’d be lying if I recommended anything.

Hey Andrew! It seems that the link to v2 is broken. Is there any place I could find those? Do you know if this design will fit an Elite Direto x?

Thanks!

Jan

I have updated the links, I’ve had people use Elite Direto Xs with my rocker plate design.

Hi,

Did you give this a go with a direto?

I am thinking of trying, but as far as I can see, the widest point of this rocker plate (the V1) is 802.208 mm, and with the feet extended, the direto measures 830mm in widt.. So the feet will be sticking out from the top plate..

I actually had a guy use it with a direto, but he folded one of the legs in at a 45 degree angle. I tried to find the photos, but had no initial luck. If I come across them I will share.

Andrew,

Your work is phenomenal and it’s amazingly generous of you to share. Thank you!

I’m going to dive in. I’ve found most of what I need, but the springs are eluding me. The provided amazon link isn’t available. Do you have a couple you’re willing to sell & mail?

sure, shoot me an email, anything at andrewgrabbs.com I’ll arrange a shipment.

that’s awesome! If you remember, send me some updates when you get it all finished. I love seeing some good CNC work.

Scott, I’m glad it was helpful. That’s always my goal. I hope you find a good deal on the CNC’ing and I took your suggestion and made a “buy me a coffee” button! Thank you!

Hi Andrew,

Will the V3 be available in Multi printabel?

Looking forward to start the project for my Wahoo Kickr..

Unfortunately, I have no plans to. A nice guy on the Facebook Rocker Plate group page made print outs for the V2.

Thank you for quick answer. Did not fond the v2file in the fbgroup so I went for the V1. Question: How do I center the trainer the easiest way on the top plate (Wahoo Kickr).

On my design there is a center line. I try to get the bicycle + trainer centered as best as possible to that line and then add the counter weight as necessary.

Hey Andrew, great work with the design and thanks for posting.

I’m currently using a Wahoo Kickr Core and wondering where this is compatible with your design? I’m looking to assemble all the parts together and get building soon.

Cheers,

Lee

Thanks Lee!

The Kickr Core should work fine with the V3 design.

Lee,

That’s correct, the V3 is just wider rear platform. It also has a lot more material removed from the base, but this was to reduce shipping weight, it’s not necessary.

David,

Thanks for the support! As for the linear bearings, they should be fine, once you load them up with weight I don’t imagine you’ll notice them “sticking”.

You’re right: Got it built, and they move fine, side to side. They are a little rough fore and aft, however. Do you recommend adding a little machine oil?

Posted to the FB Rocker Plates Group:

https://www.facebook.com/groups/415329188897706/permalink/1815140525583225/

David,

I always throw a little grease inside the bearings and on the rail just for longevity of the bearings and rod. I’m sure machine oil would be fine.

Have you determined if there would be a weight limit rider and bike. I’m a bigger guy about 275lb with my surley midnight special, and kicker core with axis feet

Daniel,

The board is about 152.4cm in length, as long as you back the trainer up to the back I think you’ll be fine.

Hi Andrew.

Nice work you have done.

Do you have access to DGW or DXF files that you want to share, then it is possible to edit the files.

I do not, unfortunately.

Christopher,

I didn’t get the chance to use 6″ balls, but I don’t think they pose that big of an issue assuming they are pliable enough and you can get them wedged in there. I only inflate the balls enough to give them some shape, stick them in and pump them up in place to the desired PSI.

My other question in regards to spring location between the bearings and your video how you have it shown is this with the appropriate spacing where the screw holes are on the top plate?

The video was a prototype and the schematics are updated. The springs should go between the standoffs and the linear bearings.

Hi Andrew is there still an available source for springs and balls for your rocker plate design. I’m in the process of building one and having trouble sourcing the springs and balls.

Brian

Brian, are you in the states? I can sell you some I have left over.

I am in the states (Massachusetts), I found the springs but still need the balls. I know they are available and people use all types but the links in your doc come up unavailable. What are you using?

Mostly 5″ playground balls. Here are some: https://amzn.to/4aKvmmH

How much would you sell a pair for? Im in Charlotte NC

Hey will this V3 also accommodate a kicker bike ?

Yes it will. I use my Kickr Bike on it with no problem.

I can’t seem to source a 5×5 piece of plywood in my area. Do you think this could be done on two 4×4 boards if placed diagonally?

That I am unsure of. The only thing that may cause an issue would be the back end of the top plate. You should be able to mock it up in the CNC software you’re using and see.

Can I ask why on V3 files the top plate is in imperial and the bottom plate is in metric. If I just scale the imperial up 25.4 will that be accurate enough?

Most of the bolts and measurements I used were metric, but the birch plywood sheets I could get were all imperial. Likely I just missed a conversion in solidworks. If you’re referring to the print outs, another guy labeled all of those.

Patrick, you are correct. There are two linear bearings that go in the center of two linear rod supports. The space between each linear rod bearing and support will need a spring.

Andrew

Yes I have the springs. But my question is the compression of the 5 1/4″ spring to 3 5/8″.

Does that give your desired motion and is it fairly stiff?

it works really well for the ones I have built, if you want less maybe you can cut them?

Hi Andrew,

Mate I’ve converted the Scs20uu v3 to pdf then scaled to 525% it seems like the holes align well enough. Just checking to see if you know before I start cutting

My apologies, but I don’t know the first thing about PDF conversions and what % would work. A nice guy on the facebook group did the original multipage conversions. You may have luck asking the group.

Thanks for the reply Andrew

Thought it might be a long shot but worth a go. I think I’ve sorted it. The measurements between the holes for the bearings and mounts are spot on so I’ll run with it

Cheers again for your designs

that’s good to know, Thank you for sharing!

I have a newer model Wahoo Kickr that I’m planning to bolt directly into the top plate using longer bolts like you mentioned in the video. Do you have specifics on length and size?

I used M10x100mm bolts. These ones to be exact: https://www.fastenal.com/product/details/11506188

What bit[s] do you use for the CNC? Do you use a roundover for the outside edge & handles? Thank you!

Ryan,

I don’t actually have a CNC, I take the DXFs to a local company and they handle the processing.

Hi Andrew, many thanks for the blueprints and videos. I have just completed my rocker plate. It’s an awesome build and first ride was great

Thanks again

I am glad to hear it. Cheers!

Andrew, will a 2020 Kickr fit on the V1 version of your design?

Brian

V3

There seems to be a problem with the scale in these files. One element measures 581,201 x 1524 mm, while the other is only 31,624 x 59,865 mm.

What are the correct sizes?

they should be 60″ in length.

shouldn’t

10 Bottom Plate Bolts 6EY59 M6-1.0 30mm 16

be 8pcs instead of 16?

yes, the bottom rod supports only require 2 bolts.

Hello Andrew,

I just machined one of these on the CNC. I found when assembling that I needed to put a 1/8 spacer on top of the linear bearing in order for the top plate to rock with out hitting the 20mm rod mounts.

Andrew,

Sorry I missed the note about the risers. That is exactly what I did. Thanks

Hey Andrew,

I asked a friend if he could CNC the plates for me. Unfortunately, he said he couldn’t because the files are in imperial measurements instead of metric. Could you provide files with metric measurements?

Andrew, the local printshops are all telling me the single printable is a small image – 3 x 7 inches & 4 x 8 inches. How to I get the files to by the right size to print for the top and bottom boards? Thanks for everything here, so close to getting the rocker board up and running.

1. You should have around 2-4 inches depending on how many risers you use.

2. Realistically your probably going to get about 3-4 degrees.

Hello Andrew, congratulations for providing all the information on this channel.

I’m not good at interpreting plans and in the printables (simple) there are some measurements that I can’t find.

Your help is possible? Thank you

Andrew what is the width of the plates

the dimensions are cut off in the files you provided

thx in advance

Hi Andrew,

Thanks for sharing your excellent plans. I’m going to try and make the rocker without the CNC. I do not see anywhere in your plans what the width of the top and bottom plate are. Could you give me those dimensions at their widest point. Thank you. Art

I’m about to tackle the plate build, but had a quick question first if that’s ok? I have a Wahoo BIKE V1 (the whole trainer bike). Are you aware of anyone using this with your rocker plate? Success? Fantastic! Mat

Hi Andrew,

Do you have plans for the top and bottom plates with dimensions?

I would be willing to pay for them.

Thanks

Hi Andrew,

Thanks for all the information an links to the different sites for all the parts.

Next are the base and top plate. Like one of the other visitors also mentioned, do you have a plan with the measurements on it?

I love this the only thing i really miss i measurements i cannot find anything in that dxf reader files etc 🙁

Otherwise really nice

I’m planning to build this with a completely free front wheel. This will allow for a shorter rod and mechanism. I’ll send it to you when its done. BTW, I was wondering how wide the top plate is.

Br,

Steve

Hi Andrew – greetings from Sydney Australia! Thanks so much for sharing these plans! I’ve just put mine together and works absolutely perfectly (quite apart from it being fun to make). Like everyone else here, I’m very appreciative. Thanks again